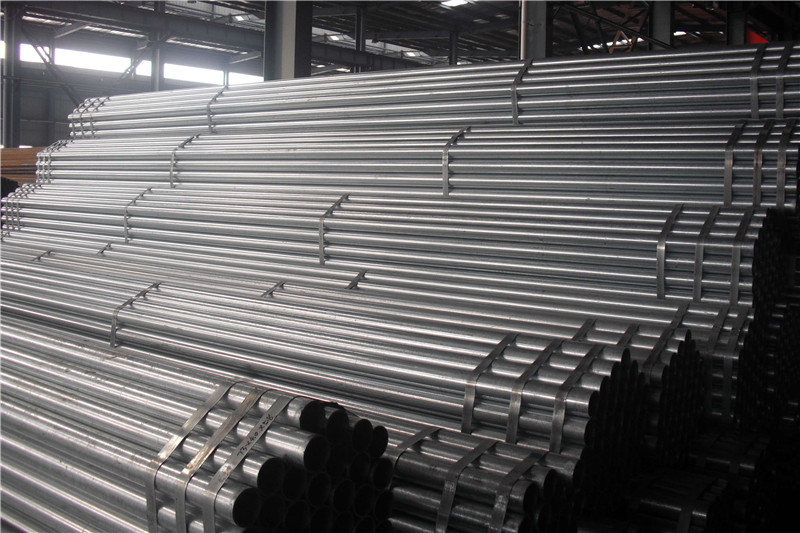

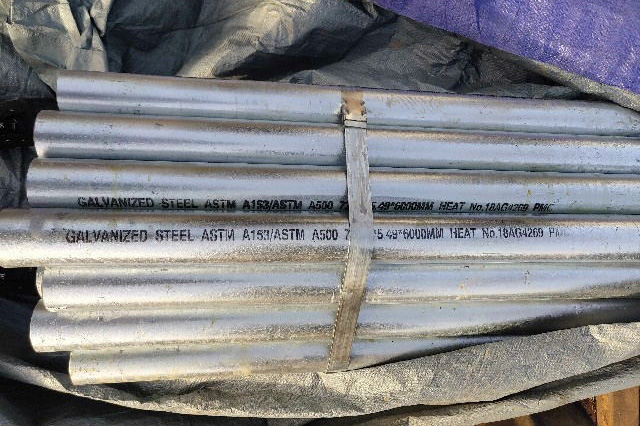

Pipa baja galvanis listrik / Hot-dip

Pipa baja galvanisyaiku pipa baja karbon sing dilapisi lapisan pelindung seng.Lapisan seng dadi lapisan kurban, bakal teyeng sadurunge baja karbon ing ngisor iki.Pipa baja galvanis kalebu rong jinis: pipa baja galvanis panas lan pipa baja galvanis sing adhem.Lapisan galvanis bakal ngiyatake kinerja anti-karat pipa baja.

Hot dip galvanizing kanggo nggawe logam molten lan reaksi matriks wesi minangka lapisan alloy, supaya landasan lan lapisan loro digabungake.Hot dip galvanizing kanggo pickle pipo baja pisanan, supaya mbusak oksida wesi ing lumahing pipe baja.Sawise pickling, liwat amonium klorida utawa seng klorida solusi banyu utawa amonium klorida lan seng klorida dicampur banyu tank solusi kanggo reresik, lan banjur menyang hot dip plating tank.Hot-dip galvanizing nduweni kaluwihan saka plating seragam, adhesion kuwat lan umur layanan dawa.Perawatan galvanis listrik kanthi permukaan sing entheng lan apik uga bisa diwenehake.

Proses Hot Dip Galvanizing:

Bahan kerja degreasing → ngumbah → pickling → ngumbah → pengeringan solvent dip fluxing preheated hot dip galvanis → cooling → finishing → rinsing → pengeringan → tes pasif

Proses galvanis kadhemen:

Chemical degreasing → ngumbah → banyu panas banyu panas elektrolisis degreasing → ngumbah → ngumbah → paduan wesi galvanis korosif sing kuat → ngumbah → ngumbah → cahya → ngumbah → pasif garing

Bahan bangunan lan struktur

Tujuan teknik mekanik lan umum

Produksi body bus